UAE Industry 4.0: 2026 Guide to Smart Factory IoT, Green Manufacturing in the UAE, and 3D Printing in Dubai under Operation 300bn

Estimated reading time: ~7 minutes

Key Takeaways

- The UAE’s Operation 300bn is in a scaling phase by 2026, prioritizing localization, exports, and circular economy alignment.

- Smart factory IoT adoption is accelerated via MoIAT’s TTP and the ITTI, linking maturity to incentives and preferential procedures.

- Green manufacturing advances Net Zero 2050 through electrification, hydrogen, and AI-driven energy optimization across plants.

- Dubai’s 3D printing construction framework standardizes certification, digital logs, and conformity marks for safety and durability.

- Manufacturers should follow a structured Industry 4.0 roadmap—baseline with ITTI, invest in high-ROI use cases, and harden ICS cybersecurity.

The landscape of industrial production is undergoing a seismic shift as UAE Industry 4.0 matures into a globally recognized benchmark for digital excellence. As we navigate through 2026, the Ministry of Industry and Advanced Technology (MoIAT) has accelerated its national program to integrate Fourth Industrial Revolution (4IR) technologies across the manufacturing value chain. This strategic evolution is not merely about automation; it is a comprehensive ecosystem encompassing IoT, artificial intelligence, robotics, and additive manufacturing designed to bolster national productivity and global competitiveness.

Under the latest Operation 300bn updates, the UAE is on a high-velocity trajectory to increase the industrial sector's contribution to the GDP from AED 133 billion to AED 300 billion by 2031. The 2026 milestone is particularly significant, marked by the "Make it in the Emirates" forum scheduled for May 4–7, 2026, which serves as the primary catalyst for industrial localization and high-tech investment. For stakeholders, understanding the convergence of smart factory IoT, green manufacturing UAE initiatives, and 3D printing construction Dubai regulations is essential for maintaining compliance and capturing market share in this digitized economy.

Operation 300bn Updates: 2026 Milestones and Industrial Trajectory

The "Operation 300bn" strategy remains the bedrock of the UAE’s industrial identity, functioning as a multi-decade roadmap to transform the nation into a global industrial hub. By 2026, the strategy has moved beyond foundational policy-making into a phase of aggressive implementation and scaling. The focus has shifted toward eleven priority sectors, including space technology, medical technology, and advanced manufacturing, all underpinned by the UAE Industry 4.0 framework.

Recent data indicates that the UAE's industrial exports reached record levels in the preceding years, with 2026 projections suggesting a continued 7-10% year-on-year growth in non-oil industrial output. This momentum is fueled by the "Make it in the Emirates" initiative, which has successfully localized supply chains for major state-owned enterprises and private conglomerates. The 2026 updates emphasize the integration of circular economy principles, ensuring that industrial growth does not come at the cost of environmental integrity.

Smart Factory IoT in the UAE: Programs, Incentives, and Use Cases

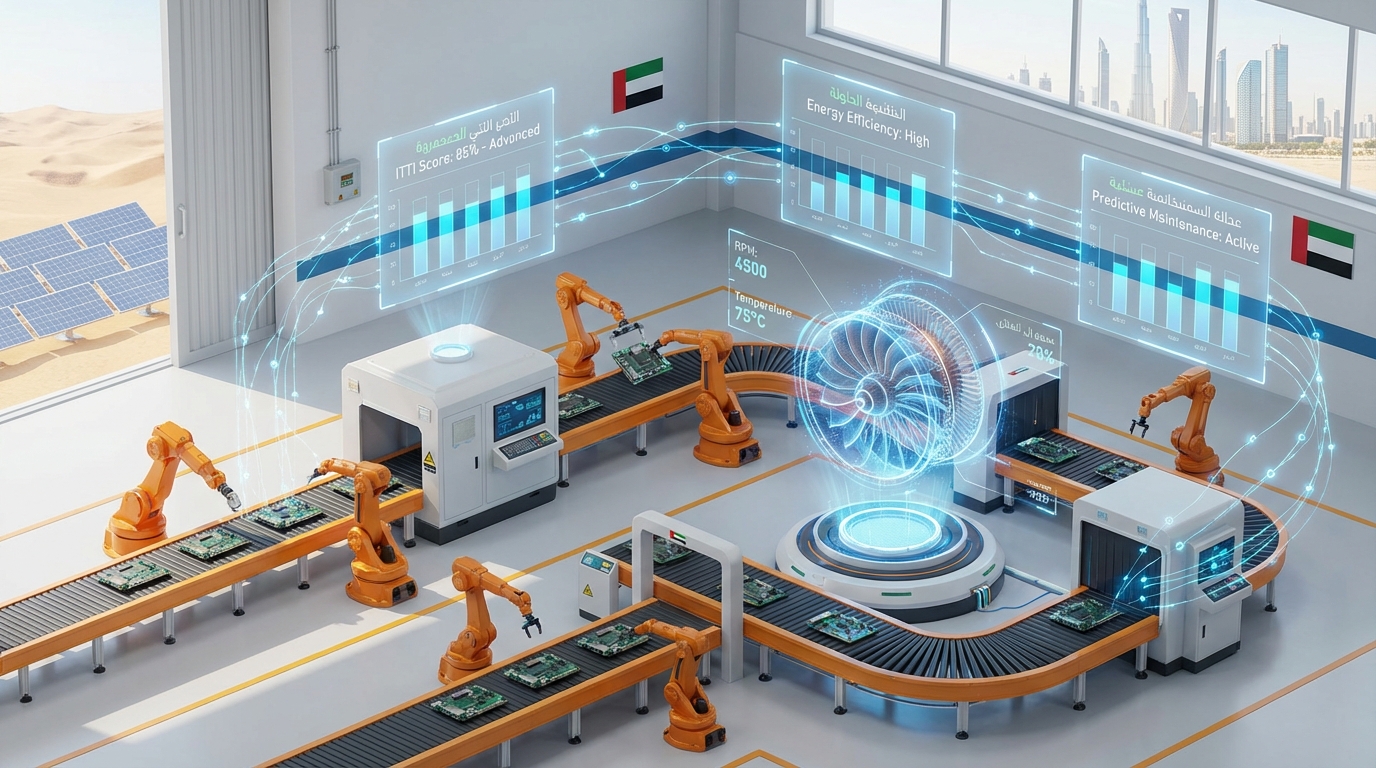

The implementation of smart factory IoT is no longer a luxury for UAE manufacturers; it is a strategic necessity driven by MoIAT’s Technology Transformation Program (TTP). This program provides the structural support needed to transition traditional production lines into data-driven ecosystems. By deploying a network of connected sensors and edge computing devices, factories can achieve real-time visibility into every stage of the production cycle, from raw material intake to final logistics.

A cornerstone of this digital transition is the Industrial Technology Transformation Index (ITTI). This diagnostic tool allows manufacturers to benchmark their digital maturity against global standards, identifying specific gaps in their IoT architecture. In 2026, a high ITTI score is increasingly linked to preferential utility rates and streamlined customs procedures. Furthermore, the "Transform 4.0" initiative provides a clear pathway for "Lighthouse" factories to share best practices, creating a collaborative environment that accelerates the national adoption of smart technologies.

In Abu Dhabi, the Abu Dhabi Industrial Strategy (ADIS) has introduced the Smart Manufacturing Incentive Programme. This program, managed by the Abu Dhabi Department of Economic Development (ADDED), offers financial rebates and technical support for factories integrating AI-driven predictive maintenance and automated quality control. Platforms like TrueFan AI enable enterprises to bridge the communication gap during these transitions, ensuring that complex technical updates are communicated effectively to a diverse, multi-lingual workforce through personalized digital content.

Practical use cases in 2026 include the use of digital twins to simulate production bottlenecks before they occur. For instance, a food and beverage manufacturer in Dubai Industrial City might use IoT-enabled vibration sensors on CNC lines to predict motor failure, reducing unplanned downtime by up to 30%. Similarly, AI-based computer vision systems are being deployed to detect micro-defects in electronics manufacturing that are invisible to the human eye, ensuring a "first-pass yield" that exceeds 99%.

Green Manufacturing UAE: Decarbonization Roadmap and 4IR Enablers

Sustainability is the new frontier of industrial competitiveness, and green manufacturing UAE initiatives are at the heart of the nation’s Net Zero 2050 commitment. MoIAT’s Industrial Decarbonization Roadmap outlines a clear strategy for reducing the carbon intensity of the manufacturing sector. This involves a shift toward process electrification, the use of alternative fuels like green hydrogen, and the implementation of rigorous carbon accounting standards.

The synergy between UAE Industry 4.0 and sustainability is profound. IoT sensors are now being used for "energy intensity monitoring," allowing plant managers to track the exact kilowatt-hour consumption per unit produced. This granular data enables AI algorithms to optimize batch scheduling, ensuring that energy-intensive processes occur during off-peak hours or when renewable energy availability is at its peak. By 2026, many UAE-based factories have integrated "Circular Economy" modules into their ERP systems to track material waste and facilitate the reuse of industrial by-products.

Furthermore, additive manufacturing (3D printing) is playing a vital role in decarbonization by enabling "lightweighting" of components and reducing the material waste associated with traditional subtractive manufacturing. In the aerospace and automotive sectors, 3D-printed parts are reducing the overall weight of vehicles, leading to significant fuel savings and lower operational emissions. The UAE's commitment to green manufacturing is also reflected in the growing number of "Green Industrial Licenses" issued to companies that meet stringent environmental KPIs, such as a 15% reduction in CO2e per unit within three years.

3D Printing Construction Dubai: Strategy, Certification, and Compliance

Dubai has positioned itself as the global capital of additive construction, with the 3D printing construction Dubai strategy mandating that 25% of all new buildings in the emirate be 3D printed by 2030. As we move through 2026, the regulatory framework has become highly sophisticated, moving from experimental pilots to a standardized "conformity marks" system. This system, launched by Dubai Municipality, ensures that 3D-printed structures meet the same rigorous safety and durability standards as traditional concrete buildings.

For developers and contractors, compliance with the Dubai Municipality (DM) certification process is non-negotiable. The process begins with a classification of the 3D printing system, including the robotic arm or gantry, the software used for slicing, and the specific mortar mix design. In 2026, the municipality requires real-time digital logs of the printing process, including ambient temperature, humidity, and layer adhesion parameters. This "digital birth certificate" for buildings ensures long-term structural integrity and simplifies future maintenance.

Implementation Roadmap for UAE Industry 4.0 Adopters

Transitioning to a UAE Industry 4.0 model requires a structured approach that balances technological ambition with operational reality. For manufacturers, the journey begins with an honest assessment of current capabilities using the ITTI framework. This baseline allows leadership to prioritize investments that offer the highest ROI, typically in areas like energy optimization or predictive maintenance.

Risks, Compliance, and the Future Outlook (2026–2031)

As the UAE industrial sector becomes increasingly interconnected, the risk profile of manufacturing operations has shifted. Cybersecurity is now a top-tier concern for COOs, as the convergence of IT and OT creates new vulnerabilities. In 2026, compliance with national cybersecurity standards for industrial control systems (ICS) is mandatory. This involves network segmentation, the implementation of zero-trust architectures, and regular "red-team" testing to identify potential entry points for ransomware or industrial espionage.

Conclusion

The evolution of UAE Industry 4.0 in 2026 represents a pivotal moment for the nation’s economic diversification. By successfully integrating smart factory IoT, championing green manufacturing UAE standards, and leading the world in 3D printing construction Dubai, the UAE is creating a blueprint for the future of global industry.

Frequently Asked Questions

What is the primary goal of UAE Industry 4.0?

The primary goal of UAE Industry 4.0 is to accelerate the integration of Fourth Industrial Revolution technologies across the UAE’s manufacturing sector.

How does Operation 300bn support small and medium-sized factories?

Operation 300bn updates for 2026 highlight several support mechanisms for SMEs, including specialized financing from the Emirates Development Bank (EDB) and the Industrial Technology Transformation Index (ITTI).

What is the ITTI and why does it matter?

The Industrial Technology Transformation Index (ITTI) benchmarks a factory’s digital maturity and identifies gaps across IoT, data, and automation. In 2026, higher ITTI scores are linked to incentives such as preferential utility tariffs and streamlined customs processes.

What are Dubai’s requirements for 3D-printed buildings?

Dubai Municipality mandates certified equipment and materials, plus real-time digital logs of printing conditions (temperature, humidity, layer adhesion). Conformity marks verify that structures meet safety and durability standards comparable to traditional builds.